OVERVIEW

The Vardhman Group is a leading producer of fabrics in India with fabrics contributing about 30% to the group’s revenue. It is one of the few vertically integrated fabric suppliers in India producing fabrics for both tops and bottoms in the apparel segment serving large retailers in USA, Europe, Asia and more.

Vardhman Fabric team is innovative with development of new products aiming to fulfill the customer’s expectation, keeping in view changing trends. Having a well equipped design and development studio; and also engaging reputed international designers in Italy, we offer variety and quality to our esteemed customers.

With a weaving capability above 180 million meters per annum and processing capacity of over 114 million meters per annum across a wide specialty fabrics’ range, the Company is geared and ready to meet the ever-growing demand for quality fabrics worldwide.

Our advantage in the Fabrics business comes from the following factors:

- Ultra modern process houses equipped with Japanese & European technology

- Dedicated product design and development cell powered by Japanese & European technology

- Liquid ammonia mercerisation plant installed under technical guidance from Nisshinbo, Japan

- Dedicated and widest variety of yarn availability in-house

- Very strong process control, which gives high quality and reliability along with good service

It is one of the few vertically integrated fabric suppliers in India producing fabrics for both tops and bottoms in the apparel segment serving large retailers in USA, Europe, Asia and more. Equipped with 1.1 million spindles , with a weaving capability above 180 million metres per annum and processing capacity of over 114 million metres per annum across a wide speciality fabrics range, Vardhman Textile is geared and ready to meet the ever-growing demand for quality fabrics worldwide.

Leadership is in the DNA of the organisation. Vardhman Textile is a market leader by far in terms of Cotton Yarn, Cotton Spandex Core Spun yarns, hand knitting yarns, Speciality yarns with different blends, Cotton Fabric, Stretch Fabric, Yarn dyed and Printed fabric, Bi Stretch and Liquid ammonia mercerized ultra soft fabric.

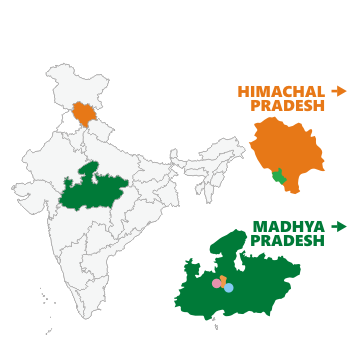

We have 18 state-of-the-art manufacturing facilities located across India and a strong export presence in more than 75 countries across the globe. Vardhman Textiles believes R & D and Innovation are pivotal to success if any organization. Vardhman invested significantly in creating state of the art R & D innovation Center. Named as CPDC (Central Product Development Center ) is Vardhman group’s nodal agency for fabric development, technical development , design development and process improvement. Centrally located in pristine mountain range of mighty Himalayas, the center broadly houses Creative Design Development Team, Product Development Team and Pilot Plant Team. With a combine head count of more than 250, the Center vindicates Vardhman’s effort in Innovation , New product Development and Service to customers.

The team of designers responsible for developing new fabric designs to be offered to the customers. This is done in the form of release of 2 collections every year. In addition to the collection, the designers develop designs throughout the year by interacting with the customers regularly, taking inspiration from their understanding of the customer requirement. Also the ideas discussed and the samples/swatches given by the customer act as catalysts for design ideas.

The center houses sample preparation machines (Handloom, mechanized deskloom and yardages(full width ) for faster service to customers. Every machine installed here are used for sample / new product development. The center utilizes best of German and Japanese machines that can make out fabric from just a single package with automation in quickest possible turnaround time. The Center takes out around 65 Handlooms / mechanized desklooms per day and around 25 yardages (full width) per day.

Our advantage in the Fabrics business comes from the following factors:

- Ultra modern process houses equipped with Japanese & European technology

- Dedicated product design and development cell powered by Japanese & European technology

- Liquid ammonia mercerisation plant installed under technical guidance from Nisshinbo, Japan

- Dedicated and widest variety of yarn availability in-house

- Very strong process control, which gives high quality and reliability along with good service

Manufacturing